Articles about vibration analysis

Vibration Measurement Units

Learn about the key vibration measurement units: mm/s, g, µm, and Hz. Understand what they mean, how they’re used, and why they matter in predictive maintenance.

Read moreVibration Measure Unit - What It Is and Why It Matters

Discover what a vibration measuring unit is, how it works, and why it's critical for predictive maintenance. Explore tools and technologies from ADASH for accurate vibration diagnostics.

Read moreInstrument to Measure Vibration

Looking for a reliable instrument to measure vibration? Discover how vibration analyzers help detect faults early, reduce downtime, and optimize maintenance.

Read moreHow to Measure Frequency of Vibration

Learn how to measure vibration frequency with precision. Explore FFT, vibration meters, and tools to detect faults early and improve maintenance.

Read moreHow to Monitor Critical Machines?

Adash has launched new software for fault monitoring. In the development phase, AI did not bring significant benefits. The analytical software is based on industry experience.

Read moreThe Vibrometer in the World of Vibration Diagnostics

A large group of customers interested in our predictive a proactive maintenance, vibration measurement and vibration monitoring products are becoming familiar with this topic and are looking for more information. For them we have prepared this article, which explains the basics of vibrometers, their uses and applications.

Read moreElectric motor faults and analysis

Asynchronous motors are the most commonly used type of motor. They are known for their advantages such as low purchase price, high efficiency, easy regulation and simple but robust construction.

Read moreMost Common Myths about Accelerometers and Frequency Range

In this article I will talk about the frequency range of accelerometers and about common mistakes in understanding them.

Read moreResonance - The Hidden Threat

You have balanced your machine properly (at least twice), you have aligned it, you have checked the mountings and it still vibrates like an old washing machine for no apparent reason... The reason is probably resonance.

Read moreSmart Online Monitoring (Maintworld magazine)

Online vibration monitoring is essential for critical machines. There are machines that need to be monitored continuously; it is not enough to take a measurtement every week, or even once per day.

Read moreHow to make vibration analysis work to perfection

In some cases, the use of applied diagnostics does not produce the expected end result. For example, a company may purchase a vibration analysis system and provide proper training to its staff, but still not get the expected results from its use.

Read morePredictive Maintenance 4.0 Knowledge (Maintworld magazine)

When I visit maintenance conferences these days, I hear quite a lot about predictive maintenance (with an explanation of what it is), much less about vibration diagnostics (usually with the comment that it is too difficult to explain and that nobody would

Read moreChoosing a machine maintenance strategy

Not using Predictive Maintenance or Proactive Maintenance today is like having a black and white TV at home. If you are using Predictive Maintenance, what are the real benefits compared to other maintenance strategies?

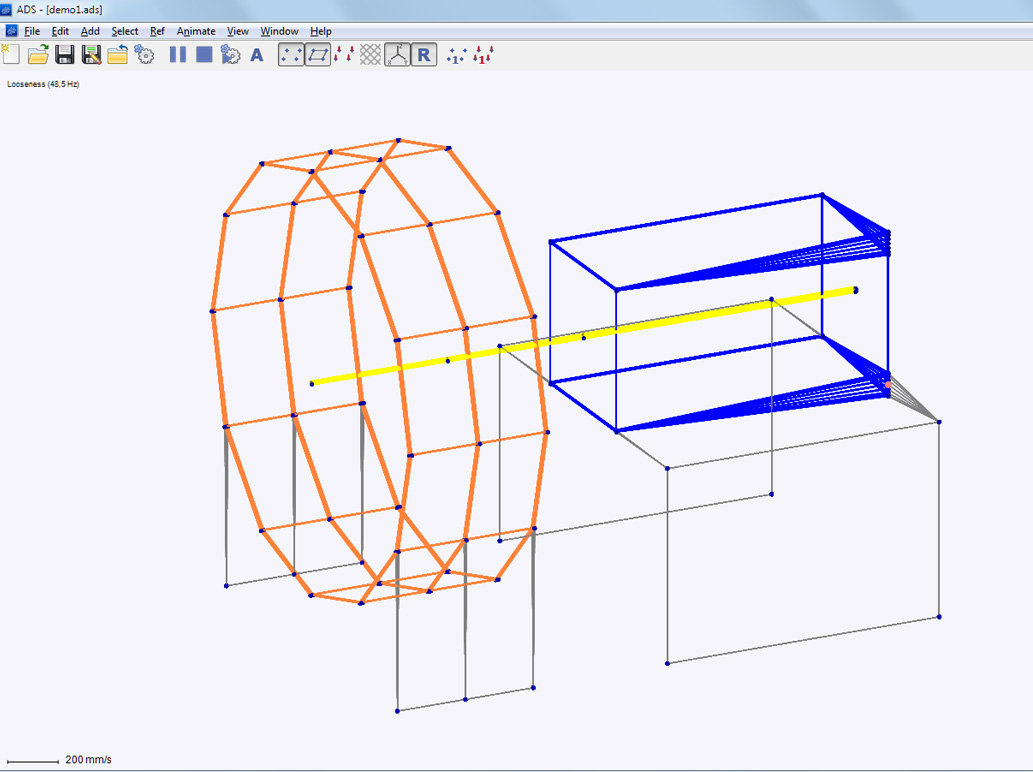

Read moreOperational Delfection Shapes (Maintworld magazine)

The Animated Deflection Shapes (ADS) is a method that can help you find the source of problems on running machines by the simple visualization of vibrations.

Read more